The automotive industry has always been at the forefront of technological innovation. From the assembly line to the self-driving car, advancements in technology have reshaped the way vehicles are designed, manufactured, and experienced. One such technology that has had a profound impact on the automotive industry is 3D design.

What is 3D Design?

3D design, also known as 3D modeling, is a computer-aided design (CAD) process that involves creating three-dimensional digital models of physical objects. These models can be manipulated, viewed from different angles, and even simulated in various environments.

The Role of 3D Design in the Automotive Industry

3D design has become an integral part of the automotive design and manufacturing process. It offers many benefits that have revolutionized the way vehicles are developed and produced.

1. Conceptual Design and Visualization

- Early-Stage Visualization: 3D design allows designers to create early-stage visualizations of vehicle concepts, enabling them to explore different design ideas and find potential issues before committing to physical prototypes.

- Realistic Renderings: Advanced rendering techniques enable designers to create photorealistic images and animations of vehicles, helping to communicate design intent to stakeholders and generate excitement among consumers.

2. Product Design and Engineering

- Detailed Modeling: 3D design tools allow designers to create detailed models of vehicle components, such as engines, transmissions, and suspension systems. This enables engineers to analyze the performance and functionality of these components before they are manufactured.

- Design Optimization: 3D design software incorporates advanced simulation tools that allow engineers to optimize the design of components for weight, strength, and aerodynamic efficiency. This leads to improved vehicle performance and fuel economy.

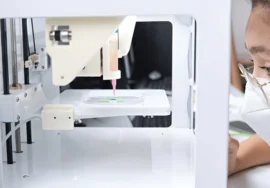

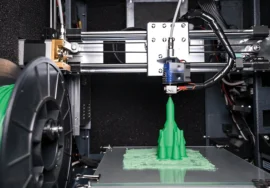

3. Prototyping and Manufacturing

- Rapid Prototyping: 3D printing technology, powered by 3D design models, enables the rapid creation of physical prototypes. This speeds up the development process and reduces time-to-market.

- Digital Manufacturing: 3D design data can be used in manufacturing processes like CNC machining and 3D printing, reducing the need for physical blueprints and minimizing errors.

4. Virtual Testing and Simulation

- Crash Testing: 3D simulations of crash tests allow engineers to evaluate the safety performance of vehicles with no physical crash tests, saving time and resources.

- Aerodynamic Testing: Virtual wind tunnel simulations help optimize the aerodynamic efficiency of vehicles, improving fuel economy and handling.

- Vibration and Noise Analysis: 3D models can simulate the vibration and noise levels within a vehicle, enabling engineers to find and discuss potential issues early in the design process.

5. Marketing and Sales

- Product Visualizations: High-quality 3D renderings and animations can be used in marketing materials, brochures, and websites to showcase vehicles.

- Virtual Showrooms: 3D technology enables the creation of virtual showrooms, where customers can explore and configure vehicles online, enhancing the buying experience.

The Future of 3D Design in the Automotive Industry

As technology continues to advance, the role of 3D design in the automotive industry is poised to expand even further. The emerging trends include:

1. Augmented Reality (AR) and Virtual Reality (VR):

- Immersive Design: AR and VR technologies will enable designers to visualize and interact with 3D models in immersive ways, leading to more innovative and intuitive design processes.

- Virtual Showrooms: Customers can experience vehicles in virtual showrooms, customizing them and taking virtual test drives.

2. Artificial Intelligence (AI):

- Automated Design: AI-powered design tools can automate repetitive tasks, optimize designs, and even generate creative design concepts.

- Predictive Design: AI can analyze vast amounts of data to predict future trends and consumer preferences, guiding the design process.

3. Digital Twins:

- Real-time Monitoring: Digital twins are virtual replicas of physical objects that can be used to monitor and optimize their performance in real-time. In the automotive industry, digital twins can be used to track vehicle performance, predict maintenance needs, and improve overall vehicle reliability.

- Remote Diagnostics: By analyzing data from digital twins, engineers can diagnose and fix issues remotely, reducing downtime and improving customer satisfaction.

Challenges and Considerations

While 3D design offers numerous benefits, there are also challenges to consider:

- Data Security: As more and more sensitive design data is stored and shared digitally, ensuring data security becomes crucial.

- Skill Gap: The increasing complexity of 3D design tools requires a skilled workforce. Training and education programs are essential to bridge the skill gap.

- Cost: Investing in advanced 3D design software and hardware can be costly. However, the long-term benefits often outweigh the initial investment.

Conclusion

3D design has revolutionized the automotive industry, enabling faster and more efficient design, engineering, and manufacturing processes. As technology continues to evolve, 3D design will play an even more significant role in shaping the future of mobility. By embracing innovation and addressing the challenges, the automotive industry can unlock the full potential of 3D design and deliver groundbreaking vehicles that meet the needs and desires of consumers.