Your Vision, 3D Printed: Revolutionizing Design and Manufacturing

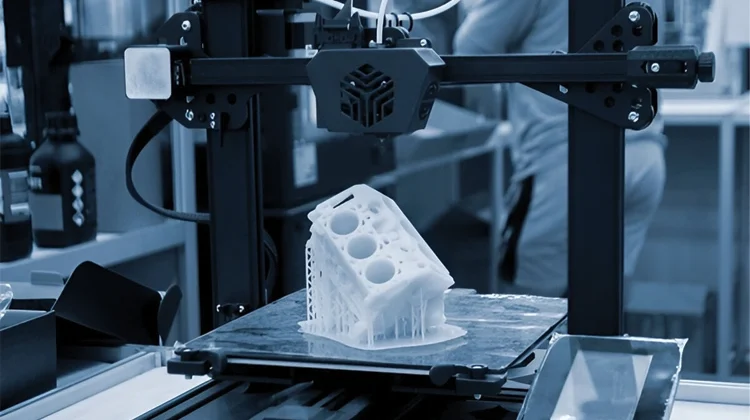

3D printing, once a futuristic concept, has now become a reality that is reshaping industries and empowering individuals to bring their ideas to life. This groundbreaking technology allows the creation of three-dimensional objects layer by layer, offering unprecedented possibilities for design, prototyping, and manufacturing.

What is 3D Printing?

3D printing, also known as additive manufacturing, involves construing objects by adding material layer upon layer. This process differs from traditional subtractive manufacturing methods, such as milling or machining, which removes material to create a desired shape.

How Does 3D Printing Work?

The core principle of 3D printing follows steps:

- 3D Model Creation: A digital 3D model of the object is created using computer-aided design (CAD) software.

- File Preparation: The 3D model is converted into a format compatible with the 3D printer, such as STL or G-code.

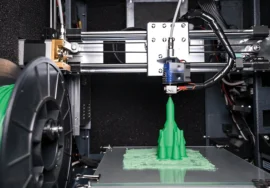

- Printing Process: The 3D printer uses a variety of technologies to deposit material layer by layer, forming the object based on the digital model.

- Post-Processing: Depending on the material and application, post-processing steps like cleaning, curing, or heat treatment may be required.

Types of 3D Printing Technologies

Several 3D printing technologies are available, each with its own strengths and applications.

- Fused Deposition Modeling (FDM): This is one of the most common 3D printing technologies, using a heated extrude to melt and deposit thermoplastic filament layer by layer.

- Stereolithography (SLA): SLA uses a laser to cure liquid resin, solidifying it into a solid object layer by layer.

- Selective Laser Sintering (SLS): SLS uses a laser to enter powdered material, fusing it to form a solid object.

- Digital Light Processing (DLP): DLP projects patterns of light onto a vat of liquid resin, curing specific areas to create layers of the object.

The Benefits of 3D Printing

3D printing offers many advantages over traditional manufacturing methods:

- Rapid Prototyping: 3D printing enables the rapid creation of physical prototypes, accelerating product development cycles.

- Customization and Personalization: 3D printing allows to create customized products, meeting individual needs and preferences.

- Complex Geometries: 3D printing can produce intricate shapes that would be difficult or impossible to manufacture using traditional methods.

- Reduced Material Waste: 3D printing minimizes material waste by only using the amount of material to create the desired object.

- Distributed Manufacturing: 3D printing enables localized manufacturing, reducing the need for long supply chains and transportation.

Applications of 3D Printing

3D printing has a wide range of applications across various industries:

- Manufacturing: 3D printing is used to create prototypes, tooling, and end-use parts, streamlining the manufacturing process and reducing costs.

- Healthcare: 3D printing is revolutionizing healthcare by enabling the creation of custom prosthetics, surgical implants, and medical devices.

- Automotive: 3D printing is used to produce custom car parts, prototypes, and tooling, accelerating the development of new vehicles.

- Aerospace: 3D printing is used to manufacture lightweight and complex components for planes and spacecraft, improving performance and reducing weight.

- Architecture and Construction: 3D printing is used to create architectural models, construction components, and custom-building elements.

- Education: 3D printing is used in education to teach STEM concepts, create educational tools, and inspire creativity.

The Future of 3D Printing: A Glimpse into Tomorrow

As 3D printing technology continues to evolve, we can expect to see even more groundbreaking applications and benefits. Here are some of the exciting trends and possibilities that are shaping the future of this trans-formative technology:

1. Multi-Material 3D Printing:

- Enhanced Functionality: By combining different materials with varying properties, such as flexibility, strength, and conductivity, manufacturers can create products with enhanced performance and functionality.

- Complex Designs: Multi-material printing allows for the creation of intricate designs that would be impossible to achieve with traditional manufacturing methods.

2. 4D Printing:

- Self-Assembly: 4D printing involves the use of materials that can change shape or properties in response to external stimuli, such as temperature, humidity, or light.

- Smart Products: This technology enables the creation of self-assembling structures and smart products that can adapt to their environment.

3. Bioprinting:

- Tissue Engineering: Bio-printing uses 3D printing techniques to create living tissues and organs, offering revolutionary possibilities in regenerative medicine.

- Personalized Medicine: Bio-printing can be used to create personalized medical treatments tailored to individual patients.

4. Desktop 3D Printing:

- DIY Innovation: Desktop 3D printers are becoming increasingly affordable and accessible, empowering individuals to create their own designs and prototypes.

- Rapid Prototyping: Desktop 3D printers enable rapid prototyping, allowing for faster product development cycles.

5. Industrial 3D Printing:

- Mass Customization: Industrial 3D printing enables the production of customized products at scale, meeting the growing demand for personalized items.

- Supply Chain Optimization: By reducing the need for physical inventory and enabling localized manufacturing, 3D printing can optimize supply chains and reduce costs.

Overcoming Challenges and Ethical Considerations

While 3D printing offers numerous benefits, there are also challenges and ethical considerations that need to be addressed:

- Intellectual Property: Protecting intellectual property rights for 3D-printed designs is a complex issue.

- Material Costs: The cost of 3D printing materials can still be relatively high, limiting its widespread adoption in certain applications.

- Environmental Impact: The environmental impact of 3D printing, particularly in terms of energy consumption and material waste, needs to be carefully considered.

- Ethical Implications: The potential for misuse of 3D printing technology, such as the creation of counterfeit goods or weapons, raises ethical concerns.

Conclusion

The future of 3D printing is full of exciting possibilities. As technology continues to advance, we can expect to see even more innovative applications that will transform industries and improve our lives. By addressing the challenges and ethical considerations, we can harness the power of 3D printing to create a brighter future.